With energy costs soaring and spoil areas shrinking, transporting dredge slurry at the optimum flow rate and concentration is paramount. In years past, dredge operators would vary the dredge pump speed, cutter speed, and swing speed to achieve acceptable dredge production with little risk of pipeline plugging or equipment over-loading. Survey engineers constantly checked the dredge position, movement, tide, and spoil area to certify that the dredge was producing what and where it was expected. Additionally, maintenance and operating crews serviced and monitored the dredge for continuous operation and any signs of problems.

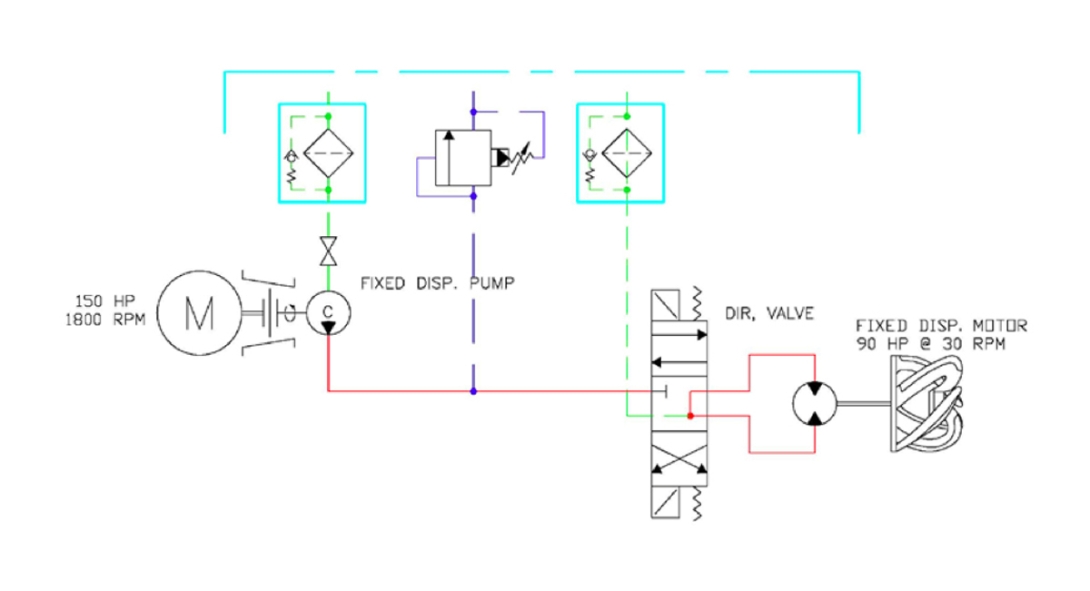

Today, many dredges employ flow control systems that vary the dredge pump speed based on the slurry flow rate and density. This type of automaton can greatly reduce energy usage while insuring a fairly consistent production rate. Often, slurry dilution automation is combined with pump speed control to allow the dredge operator the ability to maximize the dredge excavating system. Cutter/swing speed control systems are also installed to try to optimize the excavation rate. GPS positioning and digital pre, current, and post survey maps are used to assist the operator and survey engineers to control the excavator position and spoil area throughout the dredging project. Control systems also log equipment faults, alarms, and hours to assist maintenance personnel in keeping the machine operating at peak efficiency.

However, this type of automation is only the beginning of what is currently under development. With addition of a few sensors, cameras, software, and the integration of current pump speed, swing and cutter speed, GPS positioning and predictive maintenance, the dredge is being re-created as an intelligent machine that can “learn” from its environment and assist the crew in making decisions that further optimize production and reduce operating costs.